|

|

Describe the distribution of the metal on the cathode surface.The electrolytic application of thin metal coatings is one of the highest-volume chemical technologies; literally every metal-working plant has its own plating section. Among the coatings we distinguish functional types from those applied for protection and ornament. Functional coatings are used for a variety of purposes: to produce reflecting surfaces, conducting paths (in printed circuits), magnetic layers, surfaces with specific friction parameters (sliding bearings), and others. The quality and properties of metal coatings have increased sharply, because, on one hand, to advances in microelectronics, and on the other hand, to increasing uses of metal parts in corrosive environments. Since the quality and properties of electrochemical coatings, along with other factors, are determined by the thickness of the coating, the question of the metal’s distribution on the surface of the cathode have great practical importance. Especially metal is irregularly deposited on products of complex configuration. This affects adversely anti-corrosion, mechanical, electrical and other properties of the coating, since in certain areas its thickness may be less than the minimum acceptable. Under certain circumstances, more often in the depth of hollow parts (in pipes, deep holes, etc.), there is no coating at all. Speaking about the uniformity of the current distribution on the metal surface, it is customary to distinguish the microdistribution and macrodistribution of current and metal on the surface of the cathode. The term microdistribution is generally understood as the distribution of the rate of metal deposition on individual relief elements with dimensions less than 0.5 mm. Macrodistribution refers to areas with large surface contours. The uneven distribution of current on the surface of the electrodes is due to the fact that the current passing through the electrolyte on the path between the anode and the cathode meets an unequal resistance, as a result of which the density of the cathode will be different due to primarily geometrical factors. It is easier to take into account geometric factors on simple objects, using the idea of fields in electrolytes, since the primary distribution (without taking into account the electrochemical processes at the electrodes) the current distribution is determined by the configuration of the electric field characterized by the force lines. The difference in the mechanisms of macrodistribution and microdistribution of metal on the cathode surface is as follows. With good electrolyte convection, there is no appreciable difference in the thickness of the cathode diffusion layer in the macro distribution region, and geometric factors are the main reason for the unevenness. In the field of microdistribution, the thickness of the diffusion layer near the cathode is commensurate with the scale of the micro profiles, and therefore the micro profiles are unequally available in the diffusion ratio-the effective thickness of the diffusion layer differs in different sections of the micro profile. To characterize the distribution of the coating on the macro profile, the term "dissipative capacity of the electrolyte" is proposed, which means the ability to form more or less uniform coatings in thickness. The scattering ability is better the more uniform the distribution of the coating is. Sometimes (recently less and less often) the term "covering ability" is used, which means the ability of the electrolyte to give a coating covering a completely or partially relief surface without taking into account the thickness of the layer. To characterize the uniformity of metal distribution on the micro profile, the term "electrolyte leveling ability" or "leveling action" or "microdiffusing ability" is used. Although there is no generally accepted assessment of the leveling ability, often the evaluation is performed on the thickness of the metal coating that has been released at various sections of the micro profile (for example, at the top of the crest and a smooth section). The influence of various factors on the distribution of current and metal. Factors affecting the current distribution on the electrode surface can be divided into several groups: • Geometric factors (the shape and size of the electrodes, the location of the electrodes relative to each other and relative to the walls of the cell); • Electrochemical factors (variation of the cathodic potential at different current densities, electrical conductivity, current-current dependence on the current density, and factors affecting these quantities: electrolyte composition, temperature, viscosity, etc.); • "Random" factors: the nature of the metal being coated, the state of its surface, the heterogeneity of the coated metal in structure and composition, the nature of the pretreatment, etc.

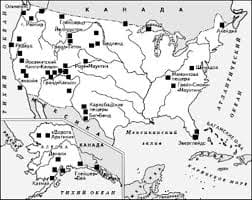

Primary current distribution for different electrode shapes: 1 - anode; 2 - cathode.   Что будет с Землей, если ось ее сместится на 6666 км? Что будет с Землей? - задался я вопросом...  ЧТО ПРОИСХОДИТ, КОГДА МЫ ССОРИМСЯ Не понимая различий, существующих между мужчинами и женщинами, очень легко довести дело до ссоры...  Система охраняемых территорий в США Изучение особо охраняемых природных территорий(ООПТ) США представляет особый интерес по многим причинам...  Живите по правилу: МАЛО ЛИ ЧТО НА СВЕТЕ СУЩЕСТВУЕТ? Я неслучайно подчеркиваю, что место в голове ограничено, а информации вокруг много, и что ваше право... Не нашли то, что искали? Воспользуйтесь поиском гугл на сайте:

|