|

|

D.C. Machinery Maintenance and Fault-FindingOnce the prime mover has been coupled to a generator shaft, the only maintenance work necessary should be to oil bearings and to ensure good contact between the brushes and the commutator. It is seldom desirable to tamper with the generator leads; for if they be wrongly re-connected, this may reverse the field. In the case of self-excited generator, this reversal of the field will cancel the residual magnetism of the field, and the generator will not build up even when the leads are properly re-connected. Residual magnetism of the proper polarity can then be restored by flashing the field. It is true that it may, very occasionally, be desired to reverse the polarity of a d.c. generator, and that this may be done by reversing the leads. But note carefully that, in this event, it is the output leads of the generator only which should be reversed. The field connections should never be reversed. The field coils are only connected to the terminal board to make their replacement easier in case of damage; and once the field wires have been properly connected in the initial installation, they should never be changed. Excess lubrication can cause faults in generator or motor operation; the lack of lubrication is more serious. A bearing which is not properly lubricated will overheat immediately, causing an expansion of the shaft and bearing assembly which may be sufficient to stop shaft rotation altogether. Lack of lubrication also results in noisy operation, by reason of the direct between the shaft and the bearing. Bearing housing should be checked periodically for overheating and noisy operation. In normal operation, the temperature of a generator or motor will rise, so that the bearing housing will heat up a certain amount. But if they heat up too much, do not add or change lubrication without first inspecting the bearing to make certain that lack of lubrication is the cause. Shafts may be forced out of line by a coupling unit, or the lubrication may not be reaching all parts of the bearing.

N o t e s

E x e r c i s e s

I. Предложите заголовок к каждому абзацу так, чтобы они составили развернутый план текста. II. Письменно изложите краткое содержание текста на английском языке (не более 10 предложений). Text 10 Commutators and Brushes Commutators and brush assemblies are another source of trouble in d.c. rotating machinery. The continual sliding of the brushes against the commutator wears the brushes down, and tends to push them out of alignment, causing bad connection between the commutator and brushes. When something does go wrong in commutation, it may be accompanied by excessive sparking, which aggravates the original trouble at once. When current commutation is taking place, however, there will be little sparking. For satisfactory commutation of d.c. machines, a continuous contact must be maintained between the commutator and brushes. The commutator must be mechanically true, the unit in good balance, and the brushes in good shape and well adjusted. These brushes are free to slide up and down in the brush holders, and are made to bear on the commutator by a spring which produces a pressure of one-and-a-half to two pounds per square inch of brush surface. Too little pressure will cause excessive brush wear. Note that the mica insulation between the commutator segments is usually cut below the surface of the segments so as to allow for wear. When there is excessive sparking at the commutator and good commutation cannot be obtained, the commutator and brush assembly must be checked, and any defects found corrected as soon as possible. The inspection procedure and the steps taken to eliminate troubles are as follows: 1. Watch the machine working to see if you can spot any arcing or excessive sparking elsewhere, which might indicate a loose connection. 2. Turn off the machine, making sure that all power is disconnected before proceeding with your check. 3. Inspect all connections and make sure that none are loose. 4. Check the relative position of the brushes on the commutator. If they are unequally spaced look for a bent brush holder. 5. Check the condition of the brushes. If they are badly worn, they should be replaced. When removing a brush, first lift the spring lever to release the pressure, then remove brush. Insert new brush, making sure that it can move freely in the holder. The end of the brush must then be fitted to the commutator by sanding (using a tape of fine sandpaper). Adjust the brush spring pressure. Check the pigtail wire and its terminal for tightness. The pigtail wire must not touch any metal except the brush to which it is attached. 6. Check the commutator for dirt, patting, irregularities, etc. Dirt can be removed with a piece of light canvas. Fine sandpaper will remove slight roughness. Never use emery cloth on a commutator. 7. A badly worn commutator should be "skimmed" on a lathe. This means machining away the irregularities of the surface.

N o t e s

E x e r c i s e s

I. Соедините предложения, употребив слова в скобках. 1. Something goes wrong in commutation. It may be accompanied by excessive sparking (when, which). 2. There is excessive sparking at the commutator. The commutator and brush assembly must be checked (if, for). 3. There is little sparking. The correct commutation is taking place (when, where). 4. The brushes are made to bear on the commutator by a spring. It produces a pressure of one-and-a-half to two pounds per square inch of brush surface (which, when).

II. Предложите заголовок к каждому абзацу так, чтобы они составили развернутый план текста. III. Письменно изложите краткое содержание текста на русском языке (не более 15 предложений). Text 11 Insulation Breakdown Under normal conditions of operation, the field and armature windings of generators and motors are completely insulated from the frame of the machine, which is bolted to the bench or floor. A resistance measurement from the frame to the armature or to the field should read infinity or several million ohms. Sometimes, however, by reason of excessive heat generated by overloading the machine, because of high moisture content in the air, the resistance of the insulation decreases and some of the current leaks through to the frame. This leakage current adds to the break-down of the insulation; and if the leakage is not found in time, the breakdown will be complete and the winding will be shorted to the frame. This will cause it to overheat or burn out. The armature and the field windings should therefore be checked at regular intervals to detect "leaks" and shorts to earth before they cause serious damage. An ordinary ohmmeter cannot be used for insulation testing in large practical machines, since, the leakage will often show itself only when a high voltage is applied to it, and an ohmmeter cannot apply a high enough voltage. An instrument called a "megger" is used instead. This supplies the necessary high voltage and is calibrated to read very high resistance values.

N o t e s

E x e r c i s e s

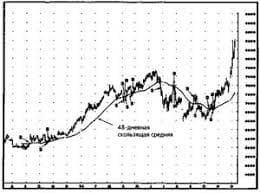

Что делать, если нет взаимности? А теперь спустимся с небес на землю. Приземлились? Продолжаем разговор...  ЧТО ПРОИСХОДИТ ВО ВЗРОСЛОЙ ЖИЗНИ? Если вы все еще «неправильно» связаны с матерью, вы избегаете отделения и независимого взрослого существования...  ЧТО И КАК ПИСАЛИ О МОДЕ В ЖУРНАЛАХ НАЧАЛА XX ВЕКА Первый номер журнала «Аполлон» за 1909 г. начинался, по сути, с программного заявления редакции журнала...  Что вызывает тренды на фондовых и товарных рынках Объяснение теории грузового поезда Первые 17 лет моих рыночных исследований сводились к попыткам вычислить, когда этот... Не нашли то, что искали? Воспользуйтесь поиском гугл на сайте:

|