|

|

Most single-pass drum roasters can effectively roast 1 lb of coffee per 5000 BTU (i.e., 1 kg per 11,606 kJ) of rated power output.

The next, and usually most important, consideration is a machine’s stated power output. Researchers estimate that 1 kg of 20°C green coffee requires 1000-1500 kJ (948-1422 BTU) to reach a medium roast.5, 32 However, the typical single-pass roaster is inefficient, transferring only a portion of its burner energy to the beans. Much of its heat is lost up the stack, and some is lost to the roasting room and other areas. My experience with dozens of different machines indicates that real-world, single-pass roasting is 50%-75% efficient. In other words, single-pass roasters consume up to twice as much energy than they transfer to the beans. Therefore, if your 12 kg machine has a rating of 100,000 BTU (105,506 kJ), your maximum batch should be approximately 20 lb (9 kg). With some experimentation, you may find that your preferred batch size is a little larger or smaller, and it will vary with different beans, but I recommend a batch size of 20 lb (9 kg) as the starting point for experimentation. Fluid-bed roasters are less efficient than single-pass drum roasters, and recirculation roasters are more efficient than single-pass machines, so they can accommodate different batch sizes relative to their burner ratings. The efficiency of a recirculation roaster increases with the proportion of heat it recycles.

Most machines have no minimum batch size, assuming they are capable of idling with constant gas settings at temperatures as low as 400°F (204°C). However, several practical considerations make roasting very small batches (those smaller than 25% of a machine’s capacity) challenging. Among other considerations, very small batches require

Less airflow. Too much airflow may suck beans out of the roaster, especially if the drum’s revolutions per minute (RPM) rate is too high.

Slower drum speeds. At standard drum RPM, the beans may ricochet around the roasting drum, which can cause uneven roasting and loss of beans into the exhaust airstream.

Setting Airflow

For years I’ve been adjusting airflow settings based on a simple test using a cigarette lighter. To perform the test, remove the trowel from the machine while a batch is roasting and the gas is on. Hold a lit cigarette lighter up the trowel hole and note whether the flame leans toward the hole, away from the hole, or remains vertical. Adjust the airflow such that the flame leans gently toward the hole, indicating a slight draw. (Increasing the airflow will pull the flame more strongly.) If the flame does not lean toward the hole, there is insufficient draw to adequately exhaust the waste products of combustion and roasting. A flame pulling strongly toward the hole, or extinguished by the airflow into the hole, indicates too much draw.

A similar test may be done by holding a small, thin piece of paper, larger than the trowel hole, up to the hole. A reasonable airflow setting should provide just enough draw to hold the paper against the hole so that it won’t fall if you let go.

Coffee roasting requires less airflow earlier in a roast and more airflow later. Once the beans begin to emit smoke and shed chaff, more airflow becomes necessary. Increasing the airflow during a roast increases convective heat transfer, so, if possible, increase airflow gradually and incrementally. A large one-time increase in airflow may interfere with the smooth deceleration of the bean-temperature progression. (See “The Bean Temperature Progression Shalt Always Decelerate” in Chapter 10.)

Some roasting machines with fuel injectors, or “power burners,” require the airflow and gas settings to increase and decrease in tandem to maintain a constant air:fuel ratio for efficient combustion. This presents a conundrum for the machine operator, since ideal roasting calls for gas settings to begin high and remain steady or decrease throughout a batch and for airflow to be relatively high later in a batch. There is no wide-ranging solution to this problem with power-burner machines, as they’re all different, and roasters must address this situation on a case-by-case basis.

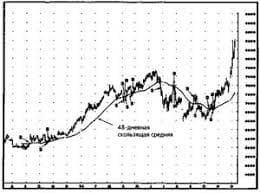

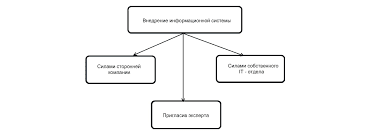

Plan a roast’s airflow settings ahead of time, knowing what the initial airflow will be, when the roast’s airflow will change, and by how much. Between batches, low-to-moderate airflow is appropriate, as it allows the operator to maintain a steady environmental temperature without using an unnecessarily large flame.   ЧТО И КАК ПИСАЛИ О МОДЕ В ЖУРНАЛАХ НАЧАЛА XX ВЕКА Первый номер журнала «Аполлон» за 1909 г. начинался, по сути, с программного заявления редакции журнала...  Что вызывает тренды на фондовых и товарных рынках Объяснение теории грузового поезда Первые 17 лет моих рыночных исследований сводились к попыткам вычислить, когда этот...  Живите по правилу: МАЛО ЛИ ЧТО НА СВЕТЕ СУЩЕСТВУЕТ? Я неслучайно подчеркиваю, что место в голове ограничено, а информации вокруг много, и что ваше право...  Что делает отдел по эксплуатации и сопровождению ИС? Отвечает за сохранность данных (расписания копирования, копирование и пр.)... Не нашли то, что искали? Воспользуйтесь поиском гугл на сайте:

|