|

|

Convection, Conduction, and Radiation

“Classic” (my term) drum roasters, which apply heat directly to the drum, cook beans primarily by convection and secondarily by conduction. Radiant heating from hot roasting-machine surfaces and between neighboring beans makes a small contribution to heat transfer as well. In a personal communication with me, a representative of a well-known German manufacturer estimated heat transfer in his company’s drum roasters to be 70% by convection and 30% by conduction.

Indirectly heated drum roasters segregate the drum from the heat source to maintain a cooler drum during roasting. Convection contributes a higher proportion of the heat transfer in these machines.

Fluid-bed roasters have no drum, and they roast by keeping the beans aloft in a high-velocity stream of hot gases. Recirculation roasters, such as the Loring Smart Roaster™, capture and reuse a proportion of the exhaust air from the roasting process. Both of these roasting machine designs transfer heat almost exclusively by convection.

At the beginning of a roast batch, charging the beans introduces a large volume of room-temperature beans and air into the hot roaster, sending the environmental temperature in the roaster plummeting. During the first few minutes of a batch in a classic drum roaster, conduction from the hot drum plays a significant role in transferring heat to the beans. As the air temperature in the roaster rebounds after its initial plunge, convection comes to dominate heat transfer. In such a machine the drum acts as a “heat-storage” device that jump-starts development early in a batch. Convection-oriented machines call for the use of hotter charge temperatures to provide adequate heat transfer early in a roast and compensate for lack of a heat-storing drum.

Establishing a high ∆T early in a roast and minimizing it by the end of a roast is essential to creating good bean inner-development and a uniform roast.

Heat Transfer and Temperature Gradient

The first two-thirds or so of roasting is an endothermic process, meaning the beans absorb energy, and heat is conducted from the outer bean to the inner bean. The temperature gradient, or “∆T,” within the beans largely determines the rate of heat transfer. Simply put, a greater ∆T causes more rapid heating of the inner bean. The ∆T early in a roast reaches an estimated 90°F (50°C),10 peaks there or slightly higher, and decreases as roasting continues.* In other words, after the first few minutes of a roast, the bean-core temperature should slowly merge with the surface temperature as they both get hotter. In general, ∆T should peak higher in faster roasts and lower in longer roasts.

Note the large ∆T at 2:00.

Heat and Mass Transfer Within Coffee Beans

Beginning at the outermost layer of a coffee bean, moisture evaporates during roasting and forms a “front of evaporation” that moves toward the bean’s center.5 The cellulose structure of the inner bean, being relatively cool, remains intact and traps moisture at the bean’s core. The heating of this trapped water produces water vapor, increasing pressure within the bean and forcing its structure to expand. This pressure, estimated by various researchers to peak as low as 5.4 atmospheres (550 kPa)8 to as high as 25 atmospheres (2533 kPa),18 builds until the stresses are great enough to disrupt the cellulose structure, at which point first crack occurs. Once the pressure, steam, and CO2 escape during first crack, the bean’s core temperature jumps.

Cross section of a green coffee been with mucilage layer.

Heat Transfer and Moisture

Both humidity in the roasting environment and moisture within beans influence heat transfer during roasting. After an initial lag, humidity in the roasting air increases the efficiency of heat transfer and causes faster moisture loss from the beans.8 Moisture content within beans has a more complex influence on roasting. Greater moisture content has three major effects on heat transfer within a bean:

It increases heat transfer because moisture increases a bean’s thermal conductivity.

It increases a bean’s specific heat capacity, meaning that the bean requires more heat energy to raise its temperature by a given amount.

The net effect is that temperature rises more slowly in moister beans than in drier beans.8 Therefore, machine operators should apply heat more aggressively when roasting moister beans and more judiciously when roasting drier beans.**

* Very fast (2-3 minutes) roasts, such as those often used in laboratory experiments, may show significantly higher temperature gradients. Roast time and peak ∆T are negatively correlated; as the value of one increases, the value of the other decreases.

** I learned this lesson the hard way during my first winter as a roaster. My green coffee had lost much moisture during storage in that season’s cold, dry air, and I found my coffees roasting too quickly. At first I didn’t know why the beans were roasting so fast, but I learned to use less heat in my roasts that winter. The next autumn I installed a humidifier in the roastery and maintained constant temperature and humidity levels all year to stabilize the green coffee’s moisture content. Roasting Machine Designs

A coffee-roasting machine is a specialized oven that transfers heat to coffee beans in a stream of hot gas while continually mixing the beans to ensure they roast evenly. Several types of roasters are in use today in the specialty coffee industry: classic drum roasters, indirectly heated drum roasters, fluid-bed roasters, recirculation roasters, and several others. Recirculation roasters return a portion of the exhaust air to the burner chamber to assist in heat generation for roasting. I will use the term “single-pass” to refer to machines that do not recirculate exhaust air. Each roaster design has distinct advantages and disadvantages, though no new design has eclipsed the popularity of the classic drum roaster, the design of which has not changed much in the past century.

Classic Drum

A classic drum roaster consists of a solid, rotating, cylindrical steel or iron drum laid horizontally on its axis, with an open flame below the drum. The flame heats both the drum and the air to be drawn through the drum. A fan draws hot gases from the burner chamber through the rotating beans and exhausts the smoke, steam, and various by-products of roasting and combustion out of the building through a vertical pipe, or “stack.” The drum’s rotation mixes the beans while they absorb heat by conduction from direct contact with the hot drum and convection from the air flowing through the drum.

At the completion of a roast, the machine operator opens the door to the drum, dumping the beans into the cooling bin, which stirs the beans while a powerful fan draws room-temperature air through the bean pile to cool it rapidly.

The best classic drum roasters have a double drum of two concentric layers of metal separated by a gap several millimeters wide. In a double drum, direct contact with the flame heats the outer drum, while the inner drum remains cooler. A double drum decreases conductive heat transfer and limits the risk of tipping, scorching, and facing. (Henceforth, these three are referred to in this text as “bean-surface burning”) If you buy a classic drum roaster, I strongly suggest finding one that has a double drum.

Advantages: The single pass of the roasting gas provides a clean roasting environment, and the drum serves as an effective heat-storage system, providing conductive heat transfer, especially during the first few minutes of a batch.

Disadvantage: Overheating the drum metal can easily lead to bean-surface burning.

Classic drum roaster. Beans (brown arrows) enter the roasting drum (1) through the loading tunnel

(2). After roasting, the beans cool in the cooling bin (3). Air (blue arrows) passes from the combustion chamber (4) through the roasting drum and exhausts through the chimney (5) by way of the cyclone (6), which traps chaff.

Single drum (left) and double drum (right)

Probat UG

To decrease costs, some manufacturers have abandoned the double drum and substituted a static plate, or "heat shield,” between the flame and drum. Despite these manufacturers’ claims, single-layer drums with heat shields are usually interior to double drums. The problem is that the heat shield gets extraordinarily hot because it is stationary and in constant contact with the flame (A double drum’s rotation prevents any one area from overheating due to continual contact with the flame.) I measured one heat shield at 950°F (510°C) with an infrared thermometer during a typical roast. The heat shield interferes with the machine operator's control at a roast by radiating large quantities of heat even when the flame is off.

Indirectly Heated Drum

Machines with indirectly heated drums send hot air from a combustion chamber through the roasting drum. This design protects the drum from direct flame contact, allowing the machine operator to use higher roasting temperatures with less risk of bean-surface burning. Like classic drum roasters, indirectly heated drum roasters mix the beans in the drum for even roasting and dump the beans into a separate cooling bin for efficient cooling at the end of a roast.

Advantages: Indirectly heated drums provide a clean roasting environment and permit faster roasting at higher temperatures, with less risk of bean-surface burning, than most drum-roaster designs.

Disadvantage: This design is a little less fuel efficient than the classic drum roaster.

Indirectly Heated Drum Roaster

This Jasper has an indirectly heated drum.

Fluid-Bed

Fluid-bed roasters rely on high airflow to keep the beans aloft and rotating in the roasting chamber. Because beans lose density as they roast, to maintain proper bean rotation these machines require very high airflow early in a roast and declining amounts of airflow as a batch progresses.16

Most fluid-bed roasters do not include a separate cooling bin; instead, room temperature air is passed through the roasting chamber at the end of a batch to cool the beans. This system is not ideal because the chamber’s surfaces are hot, which inhibits the cooling process. Many users of fluid-bed roasters buy and use separate cooling bins.

Advantages: Fluid-bed roasters are affordable and reliable, have a small footprint, and pose little risk of bean-surface burning.

Disadvantages: Excessive airflow damages flavor and decreases fuel efficiency; the machine operator must compromise between the gas and airflow settings desired for optimal flavor and those required for proper bean rotation.

A fluid-bed roaster transfers heat to beans almost exclusively by convection. Air heated in the burner box (l) passes through the roasting chamber (2) and leaves the roaster through the chimney, while the cyclone (3) traps chaff. The beans enter the roaster through the funnel (green), circulate on a bed of hot air in the roasting chamber, and exit the roasting chamber through a door (not shown).

Recirculation

In contrast to the single-pass roasters listed above, recirculation roasters send a portion of a roast’s exhaust air back through the burner chamber to recapture its heat, thereby decreasing the fuel requirements of the roasting process. These machines have recently become popular by virtue of being very fuel efficient, limiting bean-surface burning, and providing a very stable, moist, and repeatable roasting environment. The stable environment offers the side benefit of improving the ability of automated roasting software to track a programmed roast profile. The one significant drawback to these machines is a higher risk of smoky flavors in the coffee due to the beans dwelling in smokier air during roasting.

Advantages: Recirculation roasters offer fuel efficiency and fast roasting, with limited risk of bean-surface burning. They facilitate performance of automated profiling software, if any is used.

Disadvantage: Roasters sometimes report development of smoky flavors.

This recirculation roaster sends most of the exhaust air back through the drum and transfers heat almost exclusively by convection. In this design the burner also serves as the afterburner, incinerating particulate in the exhaust air before sending a portion of it up the chimney. The white arrows represent airflow. As in the drum-roaster illustration, beans enter the roaster through the green funnel, roast in the roasting drum (orange), and cool in the cooling bin (blue).

The Lilla (left) is on early attempt at a recirculating-air design, while the Loring is the best-in-class design. Progression of a Roast

Roasters tend to focus most on the first and last stages of a roast batch, known respectively as the “drying phase” and “development time.” While these terms have some validity, they’re oversimplifications that can lead to misunderstanding of the roasting process. As we’ll see, the entire roast curve influences drying and development during roasting.

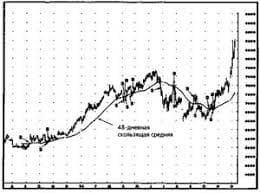

The Illusion of the S Curve

Roast profile curves generally follow an “S” curve in which bean temperature drops precipitously for 70-90 seconds, bottoms out, and then rapidly increases. In reality, bean temperature does not drop: The beans enter the roaster at room temperature and immediately get hotter. The apparent initial temperature decrease is an artifact of the air in the roaster influencing the bean probe, as well as the probe’s thermometric lag. I recommend not getting too hung up on the first 2-3 minutes’ worth of bean-probe readings; in most roasting machines the bean probe becomes a useful guide sometime during the third minute.

The S curve is the standard representation of bean-probe temperature readings during a roast. After bottoming at "the turn,” the probe’s readings increase rapidly at first and then at progressively slower rates throughout the remainder of a roast.

I cannot overemphasize this fact: The bean-probe readout is merely a proxy for the surface temperatures of the bean pile. It does not perfectly represent the surface temperatures of the beans. It’s not necessarily that the probe is inaccurate; the probe is merely doing its job of reading the temperature of the media in which it is immersed. In the case of coffee roasting, that medium is a combination of beans and hot gases.

As the graphic above shows, beans lose moisture at a steady rate until first crack. (Adapted with gracious permission from: Bottazzi, D.; Farina, 5.; Milani, M.; Montorsi, M. (2012) A numerical approach for the analysis of the coffee roasting process. Journal of Food Engineering. H2, 243-252. Original data compiled by: Schenker, S. (2000) Investigations on the hot air roasting of coffee beans. Swiss Federal Institute of Technology, Zurich.)

ЧТО И КАК ПИСАЛИ О МОДЕ В ЖУРНАЛАХ НАЧАЛА XX ВЕКА Первый номер журнала «Аполлон» за 1909 г. начинался, по сути, с программного заявления редакции журнала...  Что вызывает тренды на фондовых и товарных рынках Объяснение теории грузового поезда Первые 17 лет моих рыночных исследований сводились к попыткам вычислить, когда этот...  Что способствует осуществлению желаний? Стопроцентная, непоколебимая уверенность в своем...  Что будет с Землей, если ось ее сместится на 6666 км? Что будет с Землей? - задался я вопросом... Не нашли то, что искали? Воспользуйтесь поиском гугл на сайте:

|